GeT Educated

LEATHER PRODUCTION

The process of leather production involves several stages, providing a comprehensive understanding of how leather is made. At El Montaza, we are passionate about leather manufacturing and aim to educate others on the intricate details of this craft.

Leather Production:

A Step-by-Step Explanation

Prepare Raw Materials:

The process begins with raw animal hides, typically obtained from commercial leather-making suppliers. Hides are preserved in rock salt for up to 30 days, and later, the salt is removed through tumbling and hammering. Soaking drums rehydrate the

hides, removing salt and grime. Hides are treated to remove hair and flesh, followed by slicing into two layers: the reticular segment for inferior leathers and the papillary segment for high-quality full-grain leathers.

Tanning:

Hides are placed in drums with chromium salts or vegetable tanning agents for approximately eight hours. This halts decomposition and preserves the hide, softening it in the process. Sammying, or moisture removal through pressure, follows, along with sorting and shaving for uniform thickness

Re-Tanning:

The leather undergoes re-tanning to modify its features for specific uses. A combination of vegetable matter and chromium salts is applied, and hides are machine-dried to remove moisture. Mechanical softening enhances suppleness.

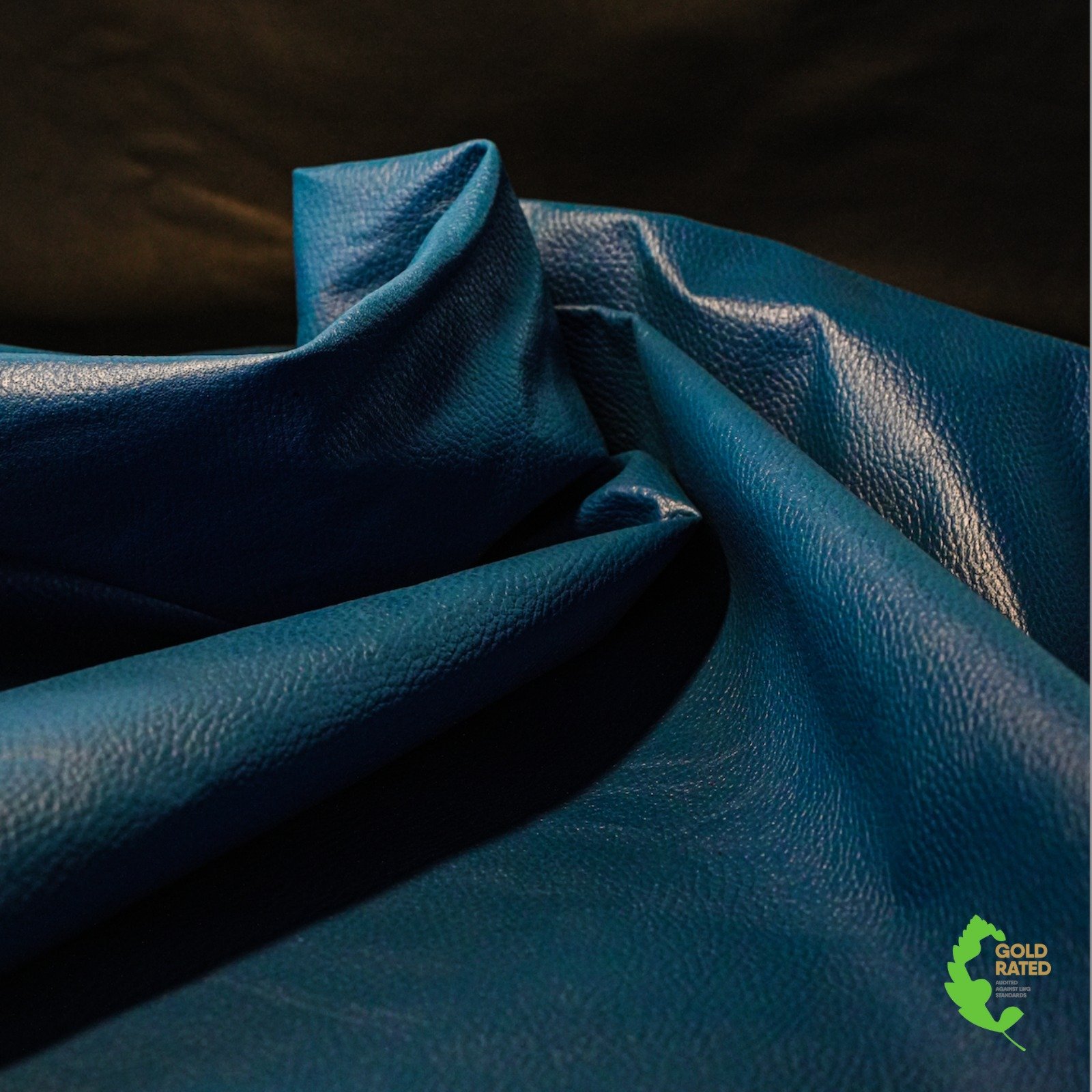

Dyeing:

Hides are dyed in drums, ensuring saturation by 100% of the dye. After dyeing, hides are air or vacuum dried. Different types of leather may require specific color dyes, such as vegetable-tanned leather with its unique color.

Finishing:

An optional step, finishing ensures softness, malleability, and the desired level of gloss. Grinding, stretching, and minimal applications of pigment or surface finish may be involved to achieve the desired appearance.

Inspection:

Quality tests, including dimensional stability, abrasion, fading, and color, are conducted. Approved hides are stamped and labeled, then rolled or draped for shipment.

What is Leather Made From?

Leather can be made from the hide of various animals, with Sheep, Buffalo, Baby Buffalo and cowhide being the most common. Other sources include a minimal percentage from exotic animals. The leather industry often utilizes by-products from the meat and dairy industries.

How to Make Leather:

Automation vs. By Hand

The process of making leather has evolved with technological advancements. Automation in modern tanneries has significantly expedited the leather-making process. However, traditional handcrafting methods still exist, involving steps like soaking, scraping, de-hairing, drying, tanning, cleaning, sleaking, and smoking.

How Leather is Made:

LEATHER FALLS INTO THREE MAIN CATEGORIES:

01

Top-Grain Leather: Contains the outer layer or grain, with types like full-grain, corrected

grain, and nubuck.

02

Split Leather: Derived from the corium after separating the top grain, resulting in suede, bicast leather, and patent leather

03

Bonded Leather: Utilizes leather scraps bonded with latex or polyurethane onto a fiber

net.

Environmental IMPACT

While the leather-making process raises environmental concerns, leather products’ durability can offset the impact. The Leather Working Group assesses tanneries for their environmental practices. Additionally, synthetic alternatives like vegan leather have their own environmental drawbacks, such as plastic usage and shorter lifespan.

The Leather Process

The leather-making process varies worldwide, with Egypt, China, Brazil, India, Italy, Korea, and Russia being major producers. Curing, an early preservation step, prevents hide deterioration. The finishing stage, though optional, allows for unique effects, including the insertion of mother of pearl or embossing.

Hides are commonly sourced from animals in these nations and are subsequently transported for processing. A luxury designer in France might procure leather from China, transporting it to Italy, renowned for its tanning techniques. The finished leather is then re-imported to France for the production of handbags or shoes.

The leather-making process involves numerous steps and approaches. Curing is a crucial phase, irrespective of other processes, and leather finishing offers a creative space for achieving distinctive outcomes.

How to Preserve Leather

Leather preservation occurs at the initial stages of the tanning process. This is vital as raw hides and skins must be shielded from deterioration or rotting before commencing the leather-making process. Preservation methods include salting, chilling, freezing, and the use of biocides.

Curing serves to prevent bacterial growth on the hide and significantly reduces its moisture content. An effective method is wet-salting, involving heavy salting and tightly packing the hide for up to 30 days. Another approach is curing through soaking in salt water

Achieving the Final Look: Leather Finishing

While not all leathers undergo finishing, exploring how to finish leather is intriguing due to the potential for creating beautiful and unique effects.

For example, introducing the mother of pearl can yield a distinctive pearlescent finish. Techniques such as embossing, textural alterations, or grain patterns can also be applied. Most full-grain leathers typically skip the finishing stage and proceed directly to ironing. Ironing, utilizing heat and pressure, is a process that imparts varying levels of sheen to the leather.

Should you have inquiries regarding the leather-making process or seek specific styles or finishes, reach out to El Montaza today for assistance.

dIFFERENCE BETWEEN TANNING TYPES

Approximately 75% of the leather produced today undergoes chrome tanning, a process that

employs trivalent chromium (Cr III). This substance is not only safe but also constitutes a crucial

element in our diet, often found in daily supplements.

Contrary to some misconceptions about the leather industry, chrome tanning does not involve

hexavalent chrome, specifically chromium VI (Cr VI), which is known to be carcinogenic.

Leather Working Group guidelines effectively ensure the prevention of chromium VI formation in

leather post-tanning.

Continuous improvements in the chrome tanning process focus on enhanced uptake, reduced

chemical usage, extensive recycling, minimized water consumption, and meticulous waste

management. Chrome tanning adheres to best practices, utilizing half the chemicals required by

alternative methods and maintaining effluent content below legal thresholds. The result is

consistent leather with enduring properties, suitable for use or wear over multiple years.

Vegetable tanning stands as the oldest method in the tanning repertoire, employing extracts

from the wood and nuts of trees and shrubs. Responsible suppliers ensure that these sources

are sustainable. While this method generally takes a longer time for leather tanning, the

outcome is a leather with a distinct aesthetic and feel, aging gracefully over time.

Vegetable tanning stands as the oldest method in the tanning repertoire, employing extracts

from the wood and nuts of trees and shrubs. Responsible suppliers ensure that these sources

are sustainable. While this method generally takes a longer time for leather tanning, the

outcome is a leather with a distinct aesthetic and feel, aging gracefully over time.

Chrome-free tanning is a process that excludes chromium from the tanning process, eliminating

harmful chemicals. The resulting hides are often referred to as “wet white” due to the leather’s

white coloring after processing. This method utilizes the same manufacturing equipment as

chrome tanneries, ensuring that the durability and resilience of the leather are comparable to

chrome-tanned leather. Notably, chrome-free leathers exhibit a smaller environmental footprint

compared to chrome leather.

Chrome-free leathers offer a diverse range of colors, making them suitable for pastel shades.

They are softer, exhibit high performance, and using chrome-free tanning maintains the quality

of the leather. However, it’s worth noting some drawbacks, such as a higher production cost,

although ongoing advancements in techniques are helping to mitigate this. Chrome-free leather

finds popular applications in automotive upholstery, furniture, clothing, shoes, and bags.

Copyright 2023 © ElMontaza Tannery. Powered By Art Tech.